Dive into the world of ERP for the manufacturing industry, where streamlined processes and enhanced productivity await. Discover the key features, benefits, and challenges of implementing ERP systems in manufacturing operations.

Explore how ERP modules are tailored to optimize specific manufacturing tasks, compare different solutions available, and learn about successful deployment practices.

Overview of ERP for Manufacturing Industry

ERP, which stands for Enterprise Resource Planning, is a software system that integrates various business processes and functions into a single platform. In the context of the manufacturing industry, ERP plays a crucial role in streamlining operations, improving productivity, and enhancing overall efficiency.

Key Features and Benefits of Implementing ERP Systems in Manufacturing

- Centralized Data Management: ERP systems allow manufacturing companies to store all their data in one centralized location, making it easier to access and analyze information.

- Inventory Management: With ERP, manufacturers can effectively track and manage their inventory levels, reducing the risk of stockouts or overstocking.

- Production Planning and Scheduling: ERP systems help manufacturers optimize production processes by creating accurate schedules and ensuring timely delivery of products.

- Cost Control: By providing real-time insights into costs and expenses, ERP enables manufacturers to identify areas where savings can be made and improve profitability.

How ERP Enhances Efficiency and Productivity in Manufacturing Processes

- Streamlined Communication: ERP systems facilitate seamless communication between different departments within a manufacturing company, leading to faster decision-making and improved collaboration.

- Automation of Routine Tasks: By automating repetitive tasks such as data entry and reporting, ERP helps reduce manual errors and frees up employees to focus on more strategic activities.

- Real-Time Data Analytics: With ERP, manufacturing companies can access real-time insights and analytics, allowing them to make informed decisions quickly and adapt to changing market conditions.

- Improved Customer Service: ERP systems enable manufacturers to track orders, shipments, and customer interactions more efficiently, leading to enhanced customer satisfaction and loyalty.

ERP Modules for Manufacturing Industry

ERP systems designed for the manufacturing industry consist of various modules that cater to the specific needs and processes of manufacturing operations. These modules work together to streamline production, inventory management, supply chain, and other crucial aspects of manufacturing.

Inventory Management

Inventory management module helps manufacturers track and manage raw materials, work-in-progress, and finished goods inventory. It enables real-time visibility into inventory levels, helps in optimizing stock levels, and reduces the risk of stockouts or overstocking.

Production Planning and Scheduling

This module assists in creating production plans, scheduling tasks, and allocating resources efficiently. It helps in optimizing production processes, reducing lead times, and improving overall production efficiency.

Quality Management

The quality management module ensures that products meet quality standards by monitoring and controlling quality throughout the production process. It helps in identifying defects, implementing corrective actions, and maintaining consistent product quality.

Supply Chain Management

Supply chain management module facilitates the integration of suppliers, manufacturers, and distributors to optimize the flow of materials, information, and finances across the supply chain. It helps in reducing lead times, improving collaboration, and enhancing overall supply chain efficiency.

Shop Floor Control

Shop floor control module provides real-time visibility into production processes, machine utilization, and labor productivity. It helps in monitoring production activities, identifying bottlenecks, and optimizing shop floor operations for increased productivity.

Comparing ERP Solutions

| ERP Solution | Key Features | Industry Focus |

|---|---|---|

| SAP ERP | Comprehensive modules, real-time analytics, integration capabilities | Wide range of industries including manufacturing |

| Oracle E-Business Suite | Scalable, customizable, supply chain management tools | Manufacturing, distribution, and logistics |

| Microsoft Dynamics 365 | Easy integration with Microsoft tools, cloud-based options | Manufacturing, retail, services |

Implementation of ERP in Manufacturing

Implementing an ERP system in a manufacturing environment involves several key steps to ensure a successful deployment. From planning to training, each stage plays a crucial role in the overall process.

Key Steps in Implementing ERP in Manufacturing:

- 1. Planning Phase: Define objectives, set goals, and create a roadmap for implementation.

- 2. Selection of ERP System: Choose a system that aligns with the specific needs and processes of the manufacturing organization.

- 3. Data Migration: Transfer existing data to the new ERP system while ensuring accuracy and integrity.

- 4. Customization and Configuration: Tailor the ERP system to meet the unique requirements of the manufacturing industry.

- 5. Testing and Validation: Conduct thorough testing to identify any issues or discrepancies before going live.

- 6. Training and Change Management: Provide training to employees on how to use the new system and manage the transition effectively.

- 7. Go-Live and Support: Launch the ERP system and provide ongoing support to address any post-implementation challenges.

Common Challenges in ERP Implementation for Manufacturing:

- - Resistance to Change: Employees may be reluctant to adopt new processes and technologies.

- - Data Integration Issues: Ensuring seamless integration with existing systems and data sources.

- - Customization Complexity: Balancing the need for customization with the risk of overcomplicating the system.

- - Budget and Time Constraints: Managing costs and timelines effectively throughout the implementation process.

Best Practices for Successful ERP Deployment in Manufacturing:

- - Executive Sponsorship: Secure buy-in and support from leadership to drive the implementation forward.

- - Cross-Functional Collaboration: Involve stakeholders from different departments to ensure a holistic approach to implementation.

- - Continuous Communication: Keep employees informed and engaged throughout the process to mitigate resistance and promote adoption.

- - Data Quality Assurance: Maintain data integrity through regular audits and validation processes.

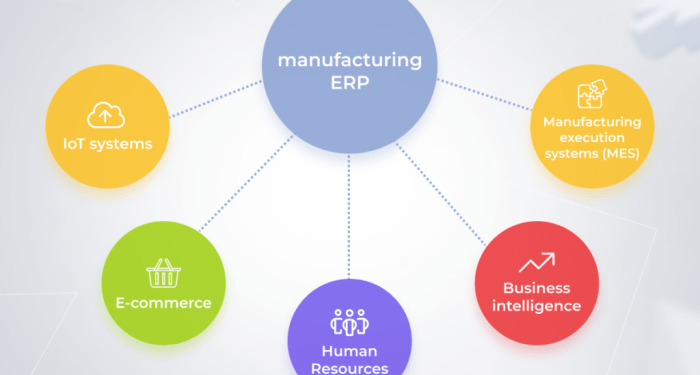

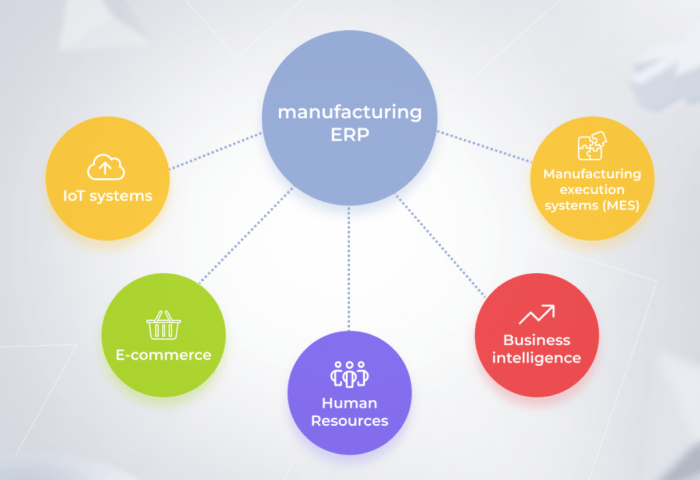

Integration of ERP with Manufacturing Processes

Integrating ERP with various manufacturing processes is crucial for streamlining operations, improving efficiency, and enhancing overall productivity. By connecting all aspects of production, from planning to delivery, ERP systems provide real-time data and insights that help manufacturers make informed decisions.

Improvement in Supply Chain Management

Integrating ERP with manufacturing processes can significantly improve supply chain management by facilitating seamless communication and collaboration between suppliers, manufacturers, and distributors. With ERP systems, manufacturers can track inventory levels, monitor production schedules, and optimize logistics to ensure timely delivery of products to customers.

- ERP integration enables better demand forecasting, leading to more accurate inventory management and reduced stockouts.

- Automated workflows and alerts help in identifying potential supply chain disruptions and taking proactive measures to mitigate risks.

- Real-time visibility into supplier performance and lead times allows manufacturers to build stronger relationships with key suppliers.

Enhancement of Inventory Control and Production Planning

ERP plays a vital role in enhancing inventory control and production planning by providing a centralized platform for managing material requirements, tracking work-in-progress, and optimizing production schedules.

- ERP systems help in maintaining optimal inventory levels by tracking stock movements, identifying slow-moving items, and reducing carrying costs.

- Integrated production planning tools enable manufacturers to schedule production based on demand forecasts, resource availability, and lead times.

- Real-time data on production performance and quality control measures allow for continuous improvement and operational efficiency.

ERP Trends in the Manufacturing Industry

As technology continues to evolve, the manufacturing industry is also witnessing significant trends and innovations in ERP systems. These advancements are reshaping the way manufacturing processes are managed and optimized.

Impact of AI, IoT, and Analytics on ERP Solutions

Technologies like Artificial Intelligence (AI), Internet of Things (IoT), and advanced Analytics are revolutionizing ERP solutions for the manufacturing sector. AI-powered algorithms are enabling predictive maintenance, demand forecasting, and intelligent decision-making. IoT devices are providing real-time data from machines and equipment, optimizing production schedules and quality control.

Analytics tools are offering valuable insights for process improvement and cost reduction.

Future Developments in ERP for Manufacturing

Looking ahead, the future of ERP in manufacturing is likely to focus on enhanced automation, greater connectivity, and seamless integration with emerging technologies. Machine learning algorithms will further improve predictive capabilities, while IoT devices will become more widespread, creating a fully interconnected manufacturing ecosystem.

Advanced analytics will continue to play a crucial role in driving operational efficiency and strategic decision-making, leading to a more agile and competitive manufacturing industry.

Last Recap

In conclusion, ERP integration with manufacturing processes is vital for efficient supply chain management and improved production planning. Stay ahead of the game with the latest trends and innovations in ERP systems designed for the manufacturing sector.

Question Bank

How does ERP enhance efficiency in manufacturing?

ERP streamlines processes, centralizes data, and improves communication, leading to better decision-making and enhanced productivity.

What are some common challenges faced during ERP implementation in manufacturing?

Common challenges include resistance to change, data migration issues, and ensuring proper training for employees.

How does ERP integration improve supply chain management?

ERP integration provides real-time visibility, optimizes inventory levels, and enhances coordination between different departments for smoother operations.

What are the future developments expected in ERP for the manufacturing industry?

Future developments may include increased use of AI for predictive analytics, further automation of processes, and enhanced connectivity through IoT devices.